Manganese Ore

Nature of operations

Gloria 1972, Nchwaning 2 1981, Nchwaning 3 personnel shaft sunk in 1999 – operational 2005, Nchwaning 3 decline sunk 1999 – operational 2005

Location: 75km north-west of Kuruman, Northern Cape, South Africa

Shallow underground (Nchwaning 3 shaft 500m, Nchwaning 2 shaft 421m and Gloria Mine 140m) mechanised bord-and-pillar mining. Processing manganese ore

Number of employees

Permanent employees – 2 541

Contractors – 3 273

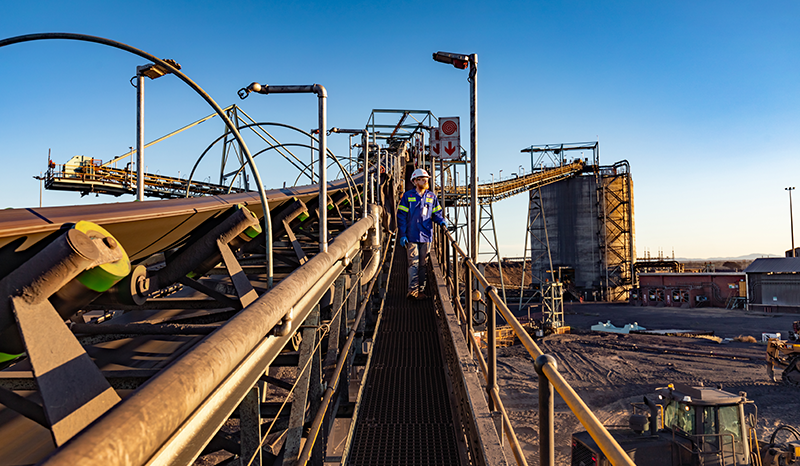

Black Rock – Nchwaning and Gloria

Manganese ore is mined in the Black Rock area of the Kalahari, in the Northern Cape. The majority of production is intended for export, but a portion is supplied to subsidiary, Cato Ridge Works in KwaZulu-Natal, and to the domestic market.

In 1940, Assmang acquired a manganese ore outcrop on a small hillock known as Black Rock. Several large properties underlain by ore were subsequently found and acquired. Manganese ore mining operations were extended and today include three underground mining complexes:

- Gloria (commissioned in 1975) producing medium-grade semi-carbonate ore

- Nchwaning 2 and Nchwaning 3 (commissioned in 1981 and 2004 respectively) producing various grades of high-grade oxide ore.

Black Rock Mine established a ten-year technology roadmap in 2018 to support its digital transformation strategy. Key projects setting the benchmark in the underground mining industry include:

- Virtual reality training centre

- Integrated remote operation centre

- Underground semi-autonomous drill rigs

- Underground battery electric vehicles – loaders and dump trucks.

The Black Rock and Gloria expansion projects were executed over 2013-2022.

The aim of the Black Rock expansion project was to support an increase in product output to a sustainable level of 4.6 million tonnes per annum by creating new underground capacity and upgrading existing underground and surface infrastructure. The scope of the project included the following key elements:

- Sinking and equipping a ventilation shaft at Gloria Mine to provide increased ventilation capacity to Gloria and Nchwaning 3

- The refurbishment of Nchwaning 1 and further underground development to deliver 200 000 tonnes per annum of product

- Upgrading Nchwaning 2, including winder refurbishment, underground development and refurbishing the process plant to deliver 1.8 million tonnes per annum of product

- Underground development and creating infrastructure at Nchwaning 3 to sustain a level of 2 million tonnes per annum product output

- Establishing a stockyard, rail loop and rapid loadout system at Nchwaning 2 to facilitate export of manganese through Transnet.

The Gloria expansion project focused on optimising existing infrastructure and upgrading the surface plant to enhance future production capacities. Other key benefits included improved grade control, buffer stockpiling, operational efficiencies with bulk materials handling, minimising fines production and optimising water use and recovery. The scope of the Gloria project included:

- Decline conveyor replacement

- 74 belts conveyor

- Mining development and underground plant (silo development and central crusher)

- Raise conveyor.

Other significant projects to have new tailings storage facilities at both Nchwaning and Gloria.

Refurbishment of the on-site rail siding and Gamagara bridge began in mid-2022. The key outcomes of the refurbishment are to maintain a safe, reliable and efficient rail line, to mitigate against ongoing maintenance costs, to maximise throughput volumes and to support the planned production ramp-up.